Taiyo Nippon Sanso Corporation (Head office: Shinagawa ward, Tokyo; President: Kenji Nagata), a Japanese industrial gas company in Nippon Sanso Holdings Group, has successfully developed a bonding paste using copper nanoparticles as a bonding material for automotive power devices. We will introduce the bonding paste to our customers and provide them with product samples. Based on the evaluation results, we will aim for the product’s full-scale commercialization.

News Release PDF

Appearance of bonding paste

1. Development background

Power devices are semiconductor devices used in inverters and other power converters for applications such as electric vehicles. The recent global shift toward electrification of automobiles makes improving the performance of power devices crucial for increasing the cruising range of electric and other vehicles. The improved performance of power devices is being achieved by the increased use of SiC devices,

which enable smaller modules and high-temperature operation.

Meanwhile, solder-based bonding materials, which are widely used in conventional Si devices, are not suitable for SiC power devices, which are expected to operate efficiently at high temperatures. Therefore, metal sintering bonding materials that use highly heat-resistant silver and copper particles are gaining attention. Silver materials used for metal sintering bonding have problems with resistance to ion migration

*1 and high cost. Therefore, there has been growing interest in bonding materials using copper nanoparticles in recent years.

*1: Ion migration is the movement of ionized metal between electrodes when a voltage is applied in a humid environment, causing a short circuit.

2. Overview of bonding paste using copper nanoparticles

We have proprietary technology to produce metallic nanoparticles through oxygen combustion.

The copper nanoparticles produced by our process have a particle diameter of about 100 nm and are coated with a layer of cuprous oxide, forming a dry powder. Unlike particles produced by conventional wet processes, our particles lack an organic protective film. This results in less outgassing during sintering

and enables low-temperature sintering.

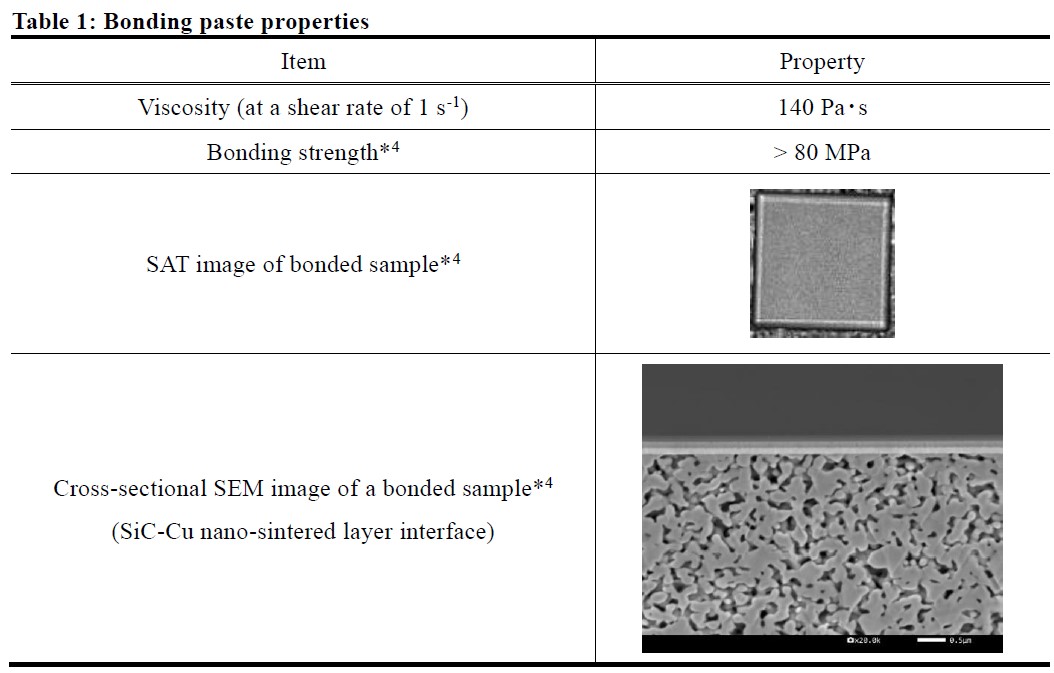

Using these copper nanoparticles, we have developed a bonding paste that enables high -strength bonding at a bonding temperature of 200°C, which has been difficult to achieve with copper -based sintered bonding materials. As shown in Table 1 below, this bonding paste has been confirmed to have a shear strength of 80 MPa or more under the following bonding conditions: a bonding temperature of 200°C, a bonding pressure of 10 MPa, and a bonding time of 5 min utes.

*4: Bonding conditions: a bonding temperature of 200°C, a bonding pressure of 10 MPa, and a bonding time of 5 min

under an N2 atmosphere

Bonded materials: a 5 mm square SiC device and a 20 mm square copper plate

Taiyo Nippon Sanso Corporation

Tnsc.Info@tn-sanso.co.jp