Initiatives toward the Realization of a Carbon-Neutral Society

One of the challenges in realizing a carbon-neutral society is to build a supply chain for green fuels that do not emit CO2, and develop the technology to use it. Specifically, a key aspect is the efficient delivery of green fuels from their production site to their consumption site. One method is to make use of hydrogen (H2) and ammonia (NH3). By combining this with the oxygen combustion technology that the Group has been researching and developing for over half a century, we can contribute to faster social implementation of green fuels.

* For more information on Nippon Sanso Holdings' environment-related activities, please visit this page.

Development of Ammonia Fuel Combustion Technology for Industrial Furnaces

Taiyo Nippon Sanso Corporation has been selected as the contractor for a project commissioned by the New Energy and Industrial Technology Development Organization (NEDO) for the development of ammonia fuel combustion technology. The aim of the project is to develop ammonia combustion technology for industrial furnaces that are currently unable to use ammonia, in order to contribute to the decarbonization of the industrial sector. Taiyo Nippon Sanso has a track record for various industrial furnaces both inside and outside Japan, including oxygen burners for glass melting furnaces. The project covers a five-year period from FY 2021 to FY 2025. Taiyo Nippon Sanso is proceeding with the development of ammonia-oxygen combustion and oxygen-enriched combustion.

Joint Development of Spherical Silica Manufacturing Technology Using Carbon-Free Fuel

Spherical silica is used as a filler for semiconductor sealants. As the scope of semiconductor applications has expanded over the past few years, demands regarding the quality of spherical silica have been increasing. The traditional manufacturing method carries a risk of carbon contamination from fossil fuels, which impairs insulating performance and reduces the reliability of the semiconductor. In February 2022, Taiyo Nippon Sanso Corporation and Admatechs Company Limited, a spherical silica manufacturer, developed a melting and spheroidizing technology using carbon-free ammonia-oxygen combustion to enable the production of high-quality spherical silica free from carbon contamination.

Successfully Melting Glass Using a Hydrogen-Oxygen Burner to Dramatically Reduce CO2 Emissions

In April 2022, Taiyo Nippon Sanso Corporation successfully conducted a verification test with 100% hydrogen combustion to melt glass using a hydrogen-oxygen burner jointly developed with Nippon Electric Glass Co., Ltd. The jointly developed hydrogen-oxygen burner can change the mixing ratio of natural gas and hydrogen as required. In the verification test, it was confirmed that melting capability equivalent to combustion using 100% natural gas could be obtained with either combustion using 100% hydrogen as fuel, or a mixture of both natural gas and hydrogen. This enables a significant reduction of CO2 emissions from melting furnaces.

Installation of CO2 Liquefaction System for Verification Test

Taiyo Nippon Sanso Corporation cooperated with Taiheiyo Cement Corporation in the CO2 liquefaction process for NEDO's "Development of Carbon Circulation Technology for the Cement Industry" project. In February 2022, the company established a CO2 liquefaction system at Taiheiyo Cement's Kumagaya Plant. The system will recycle CO2 emitted in the cement manufacturing process for reuse as a raw material for cement and civil engineering materials. Taiyo Nippon Sanso provided technical collaboration on a series of processes for liquefaction of captured CO2 in a verification test for separating and capturing CO2 from cement kiln exhaust gas.

Initiatives to Reduce GHG Emissions

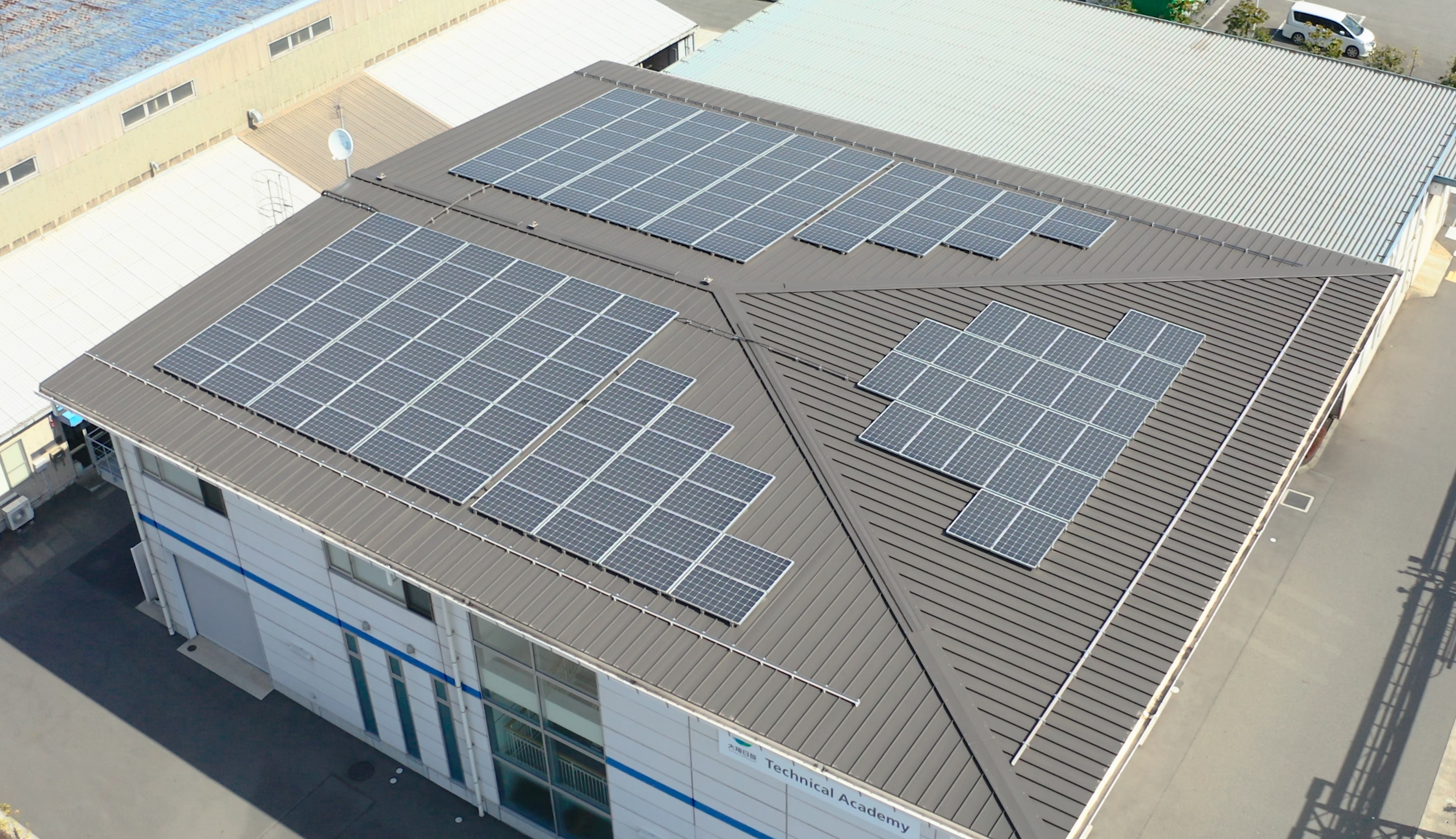

Taiyo Nippon Sanso is promoting the installation of solar panels in various locations to reduce CO2 and other GHG emissions that contribute to global warming. We will continue to promote installation in various locations.

ISO 14001 Status

The Taiyo Nippon Sanso Group strives to acquire ISO 14001 international environmental management system standard certifications, throughout the Group. To date, certifications have been acquired by 12 companies in Japan and 1 company overseas.

Results of Water Risk Assessment

The Taiyo Nippon Sanso Group conducts water stress and coastal flood risk surveys at all of its production sites in order to apprehend the risks related to use of water resources and facilitate a more effective response to water risks. The following are the results of surveys at 24 sites using the Aqueduct water risk evaluation tool developed by the World Resources Institute (WRI).

Top line: water usage (thousand m3), bottom line: number of production sites

- Reporting period: April 2022 to March 2023

- Reporting range: Taiyo Nippon Sanso and its consolidated subsidiaries. Production sites with ASU, HyCO, or liquid carbon dioxide facilities with annual water withdrawal of 20,000 m3 or more