Taiyo Nippon Sanso Corporation (Headquarters: Shinagawa-ku, Tokyo; President: Kenji Nagata; hereinafter “TNSC”), a Japanese industrial gas business company in the Nippon Sanso Holdings Group, has launched sales of Tallman Supersonic Carbon Injector (TSCi), a high-efficiency particle injector for use in the electric furnace steelmaking process. TSCi can reduce the quantity of carbon injected and electric energy used by steelmakers, and thereby contributes to the reduction of CO

2 emissions.

News Release (PDF)

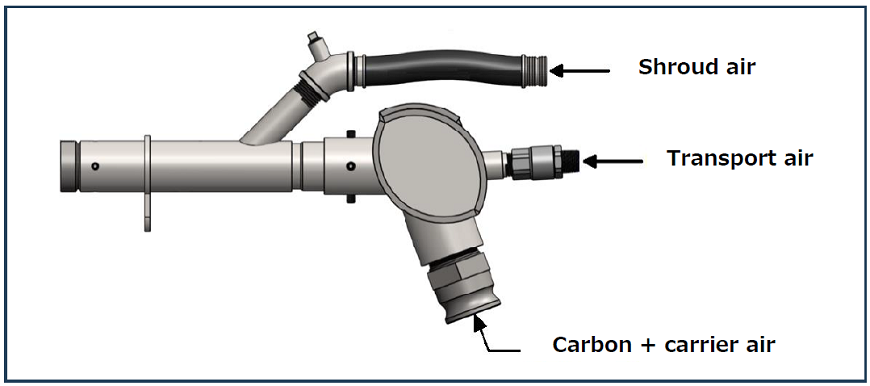

Figure 1 TSCi External Appearance

1. Background of sales

In the electric furnace steelmaking process, carbon injectors are used in many furnaces to adjust the molten steel composition. Formerly, carbon was blown directly onto the molten steel through a pipe in front of the furnace. In recent years, however, most companies have adopted a method of injection through the wall of the furnace to enhance the safety of operators and alleviate the workload. The new process involves issues of dust collection loss and a drop in carbon use efficiency. To solve them, TNSC launched sales of TSCi manufactured by Canada-based Tallman Technologies Inc.

2. Outline of technology

Carbon used in the electric furnace steelmaking process is blown into the furnace by means of a lance pipe with a single-hole nozzle attached to the furnace wall.

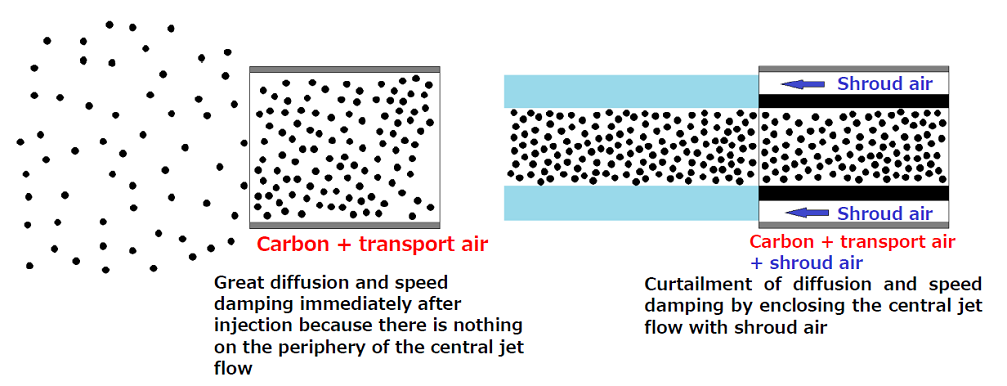

Immediately after injection, however, the carbon decelerates and diffuses, causing dust collection loss and a decline in the efficiency of carbon use. To address these issues, the TSCi has two types of air blowers: a nozzle for transporting carbon (transport nozzle) and a ring-type nozzle to curtail the damping of speed (shroud). This suppresses the deceleration and diffusion of the carbon blown out with an initial speed of Mach 2, and achieves a highly efficient injection onto the molten steel. This technology demonstrates a high injection performance not only for CDQ coke, which is used in Japan and has comparatively large particles, but for biocoke, which has good prospects for widespread use going forward for attainment of carbon neutrality (CN).

TSCi has been delivered to many companies in the United States and other countries. To utilize TSCi by companies in Japan, which use mainly CDQ coke as sources of carbon, TNSC took steps to reduce machine wear, and demonstrated a good durability.

Figure 2 Schematic Diagrams of Jet Flow (left: single-hole lance pipe, right: TSCi)

3. Effects of introduction

In operations using smokeless coal and petroleum-derived coke as sources of carbon, it was confirmed that TSCi reduced the amount of carbon injected from the furnace wall by 20% and the charge carbon injected with ironscrap by 32%. Through subsequent optimization of the operation, the company reduced the charge carbon injection by up to 85% as compared to the previous operation without TSCi. It was also confirmed that the high carbon injection performance increased the speed of slag formation, and reduced the prime units of power consumption by 3% and the iron oxide content of the slag by 3%.

Even in operations in Japan using ordinary CDQ coke and crushed coal as carbon sources, it was confirmed that TSCi decreased the quantity of injected carbon by at least 20%.

To help to build a CN society, TNSC is striving to reduce CO2 emissions at customer facilities through products that contribute to the environment. In the future, we are committed to continued contribution to CN attainment by customers, by combining new technologies created by open innovation.

Taiyo Nippon Sanso Corporation

Tnsc.Info@tn-sanso.co.jp